With the rapid development of modern industrial technology, laser cutting technology, as a high-precision and high-efficiency processing method, is widely used in metal processing. Among them, fiber laser cutting machines have become the leader in the industry with their unique advantages. This article will take the DXTECH laser cutting machine as an example to deeply explore the speed and thickness performance of the fiber laser cutting machine when cutting metal, as well as its excellent performance in cutting speed and accuracy.

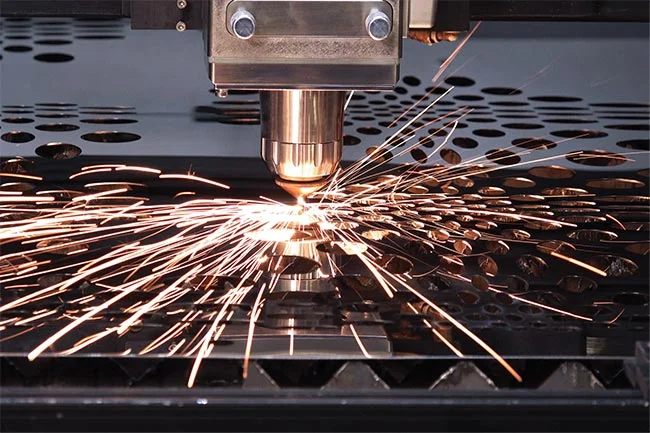

First, let’s understand the basic working principle of a fiber laser cutting machine. Fiber laser cutting machines use the high energy density of the laser beam to focus the laser on the metal surface, causing it to instantly melt and evaporate to achieve cutting. During this process, factors such as laser power, focal length, cutting speed, and the use of auxiliary gas will all have an important impact on the cutting effect.

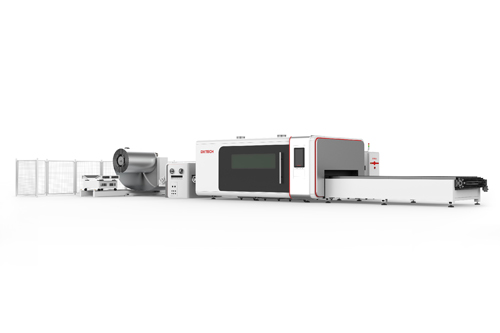

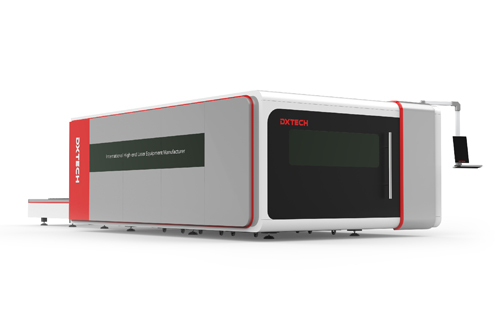

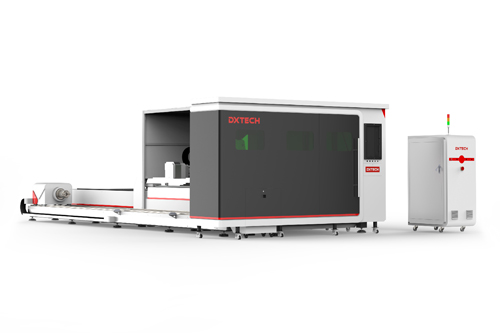

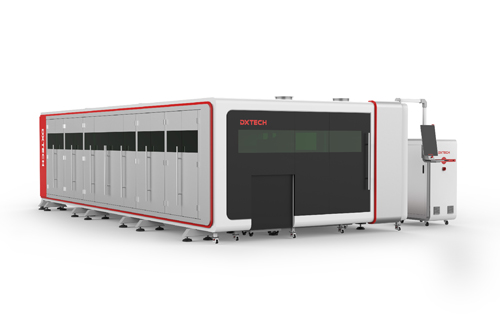

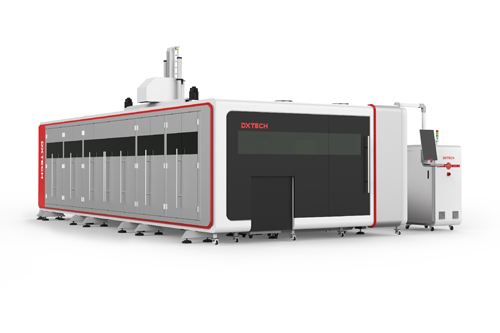

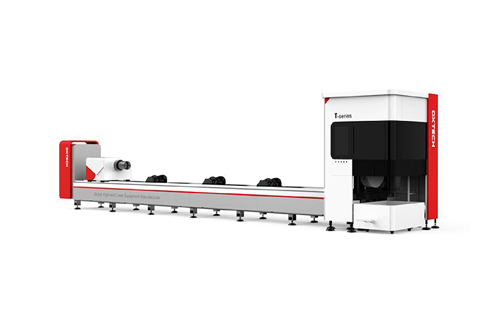

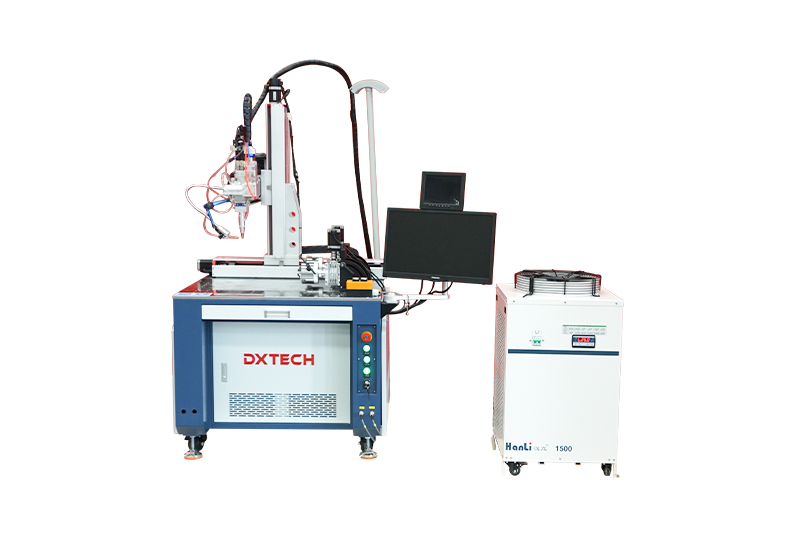

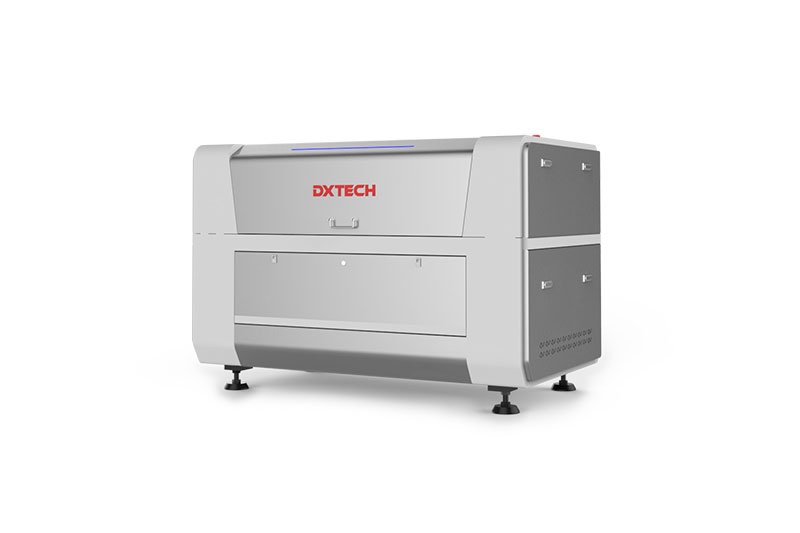

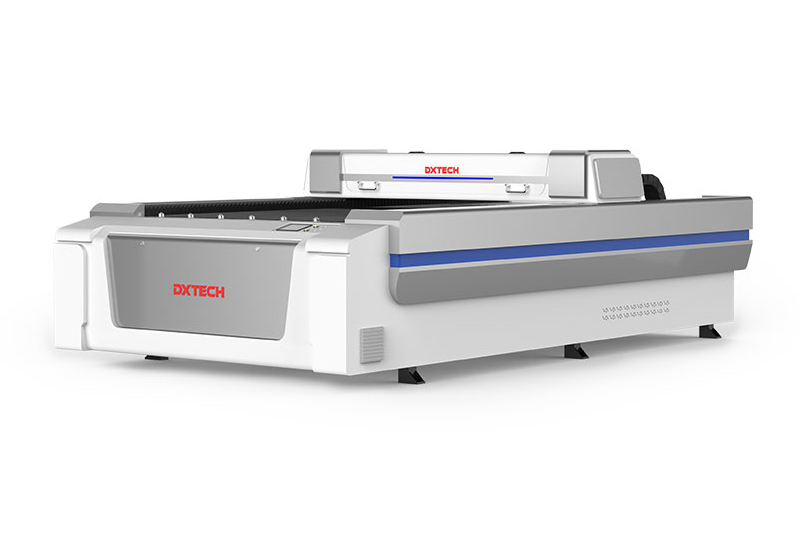

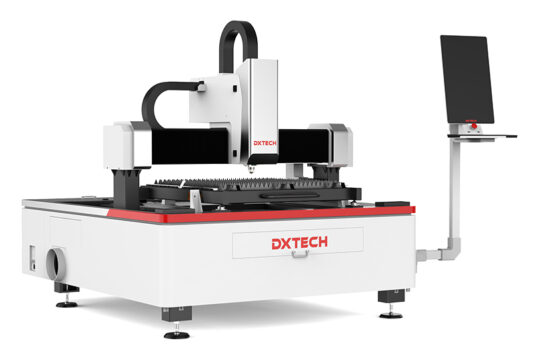

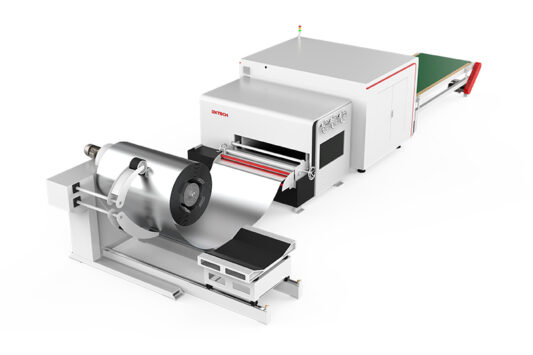

On the DXTECH laser cutting machine, we can see its excellent performance in terms of speed and precision. First of all, the DXTECH laser cutting machine adopts an advanced laser and control system, which can achieve high power and high stability laser output. This allows it to maintain a high cutting speed when cutting thicker metals. For example, when cutting carbon steel, DXTECH laser cutting machines can achieve high cutting speeds while ensuring cutting quality.

Secondly, DXTECH laser cutting machines also perform well in terms of accuracy. Through precise focus adjustment and laser beam control, DXTECH laser cutting machines can easily handle complex shapes or metal parts with high precision requirements and meet the diverse needs of customers.

Of course, the cutting speed and thickness of fiber laser cutting machines are also affected by other factors. For example, the material, thickness, and cutting environment of the metal being cut will all affect the cutting effect. In practical applications, we need to adjust parameters such as laser power and cutting speed according to specific conditions to obtain the best cutting effect.

In addition, the use of auxiliary gas is also an important means to improve cutting efficiency and quality. By blowing oxygen or compressed air, the oxidation reaction on the metal surface can be promoted, thereby increasing the laser’s absorption rate of the metal, further speeding up the cutting speed and improving the cut quality. DXTECH laser cutting machines also have advantages in this regard. The intelligent control system accurately controls the injection volume and pressure of the auxiliary gas to ensure the stability and efficiency of the cutting process.

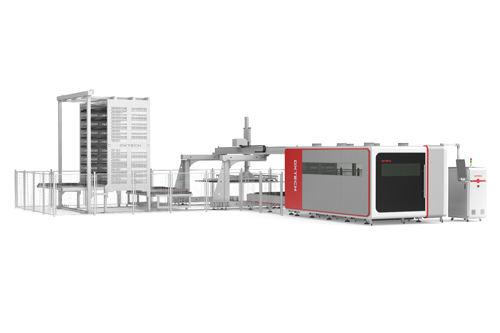

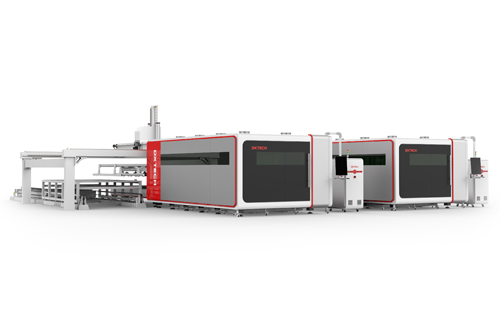

It is worth mentioning that with the continuous advancement of technology, the performance of fiber laser cutting machines is also constantly improving. Future fiber laser cutting machines will be more intelligent and efficient, capable of achieving high-quality cutting in a wider range of material thicknesses and cutting speeds. This will bring more possibilities to the metal processing industry and promote the sustainable development of the industry.

To sum up, the DXTECH laser cutting machine demonstrates the strong strength of fiber laser cutting machines in the field of metal processing with its excellent speed and precision performance. By continuously optimizing technology and improving performance, fiber laser cutting machines will continue to provide more efficient and precise solutions for the metal processing industry, promoting the prosperity and progress of the industry.

If you are interested in the DXTECH laser cutting machine, please contact us.